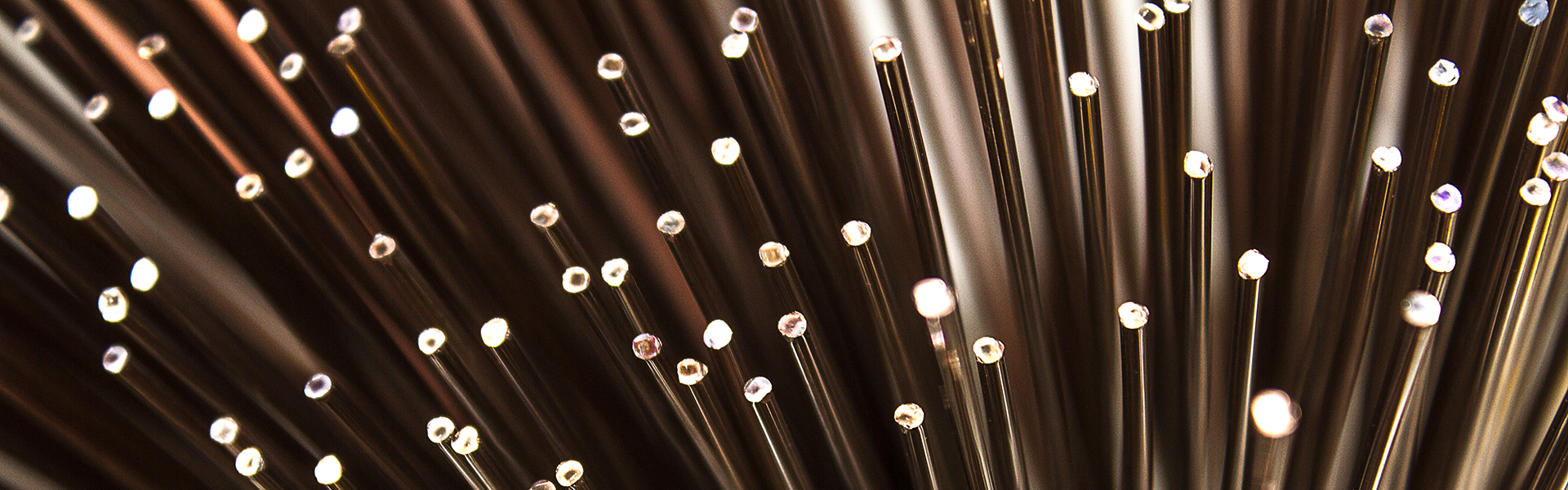

Cooper phosphorus alloys

Copper and phosphorus alloys are fitted for the grazing of copper and, with the utilization of flux, also of its alloys (brass, bronze). They have high conductivity and it is recommended the rapid heating with a torch. They are not recommended for brazing ferrous materials and inox because they can create fragile intermetallic compounds.

With the refined copper containing dissolved oxides it is appropriate to adopt a neutral or slightly oxidizing flame to avoid the formation of cavities due to the reduction of oxides, defined as fragility by hydrogen.

Phosphorus alloys should be avoid if it is used gas containing high sulfur contents. They are successfully used in hygienic sanitary pipes since, not containing zinc, they do not risk galvanizing dezincification.

Indicazioni per la brasatura del rame

Con il rame affinato contenente ossidi disciolti è opportuno adottare una fiamma neutra o leggermente ossidante per evitare la formazione di cavità dovute alla riduzione degli ossidi, definite fragilità da idrogeno.

Le leghe rame con fosforo dovrebbero essere evitate in presenza di gas contenenti alti tenori di zolfo. Sono utilizzate con successo nelle tubazioni igienico sanitarie in quanto, non contenendo zinco, non corrono rischi di dezincificazione galvanica.

Model

Composition

Working temperature (° C)

Specific gravity (g/cm3)

Standard

Details

PHOSPHORUS ALLOYS

CuP6

Self-descaling for copper-copper brazing, they require the use of flux with

copper alloys: cannot be used on ferrous materials, nickel, and aluminium. Fluidity increases with the increase of the phosphorus content. Strong brazing for the healthcare, refrigeration and air conditioning industries. Its good capillarity suggests 0.03 ÷ 0.08 mm plays.

P 6% Cu 94%

710-890

8,1

ISO 17672 Cup179

EN 1044 CP203

DIN 8513 L-CuP6

CuP7

Self-descaling for copper-copper brazing, they require the use of flux with

copper alloys: cannot be used on ferrous materials, nickel, and aluminium. Fluidity increases with the increase of the phosphorus content. Strong brazing for the healthcare, refrigeration and air conditioning industries. Its good capillarity suggests 0.03 ÷ 0.08 mm plays.

P 7% Cu 93%

710-820

8,1

ISO 17672 CuP 180

EN 1044 CP 202

DIN 8513 L-CuP7

AWS A5.8 BCuP-2

CuP8

Self-descaling for copper-copper brazing, they require the use of flux with

copper alloys: cannot be used on ferrous materials, nickel, and aluminium. Fluidity increases with the increase of the phosphorus content. Strong brazing for the healthcare, refrigeration and air conditioning industries. Its good capillarity suggests 0.03 ÷ 0.08 mm plays.

P 8% Cu 91%

710-770

8

ISO 17672 CuP 182

EN 1044 CP 201

DIN 8513 L-CuP8

TIN PHOSPHORUS ALLOYS

CuP7Sn

Suitable for furnace brazing. Used for brazing the plate packs of heat exchangers. Exceptionally smooth and with an extremely high capillarity.

P 7% SN 7% Cu 86%

650-700

8,1

ISO 17672 CuP 386

EN 1044 CP 302

AWS A5.8 BCuP-9

SILVER PHOSPHORUS ALLOYS

SB/2

Copper self-descaling products require flux on copper alloys. They allow

a good filling at lower temperatures and a good fluidity at higher

ones. Recommended particularly for sanitary and refrigeration installations with joint play of 0.06 ÷ 0.13 mm.

Ag 2% P 6,3% Cu 91,7%

645-825

8,1

ISO 17672 CuP 279

EN 1044 CP 105

DIN 8513 L-Ag2P

SB/5

Copper self-descaling product. Strong brazing of copper inserts destined for the assembly of groups subject to vibrating operations, in the refrigeration and air-conditioning industry. Suitable for 0.06 ÷ 0.13 mm plays.

Ag 5% P 6% Cu 89%

645-815

8,2

ISO 17672 CuP 281

EN 1044 CP 104

DIN 8513 L-Ag5P

AWS A5.8 BCuP-3

SB/5 S

Alloy used for the brazing of aluminum-copper, aluminum-brass, alumi- num-steel, using a specific flux. It’s ‘primarily used in heat exchangers, air-conditioning and automotive.

Ag 6% P 7% Cu 87%

650-810

8,3

ISO 17672 CuP 281

AWS A5.8 BCuP-3

SB/15

Copper self-descaling products are used for strong brazing of not-too precise joints, in the refrigeration industry for particular items such as manifold sleeves, brass distributors, capillary tubing. It has good mechanical properties at a low temperature. 0.06 ÷ 0.13 mm plays.

Ag 15% P 5% Cu 80%

645-800

8,4

ISO 17672 CuP 284

EN 1044 CP 102

DIN 8513 L-Ag15P

AWS A5.8 BCuP-5

SB/18

Copper self-descaling product. Exceptionally fluid. Designed to repair leaks in the capillary tubing of brazed joints. Useful where the heat supply is critical, because of its low operating temperature. Recommended 0.02 ÷ 0.06 mm plays.

Ag 18% P 7% Cu 75%

645-645

8,6

ISO 17672 CuP 286

EN 1044 CP 101

DIN 8513 L-Ag18P

AWS A5.8 BCuP-8

Available formats